Diesel engines are workhorses in modern transportation and heavy equipment, but tighter emissions standards have made Diesel Exhaust Fluid (DEF) systems mandatory for many vehicles. Unfortunately, these systems can develop issues that impact performance, fuel economy, and regulatory compliance.

- Table of Contents

- 1. What Is a Diesel Exhaust Fluid (DEF) System?

- 2. Why EEPA Diesel Exhaust Fluid Systems Fix Matters

- 3. How DEF Systems Work: Step-by-Step

- 4. Top 10 Common DEF System Problems

- 5. How to Diagnose DEF System Issues

- 6. Proven Solutions & Fixes

- Fix 1 — Remove DEF Crystallization

- Fix 2 — Resolve DEF Freeze Cycling Fault

- Fix 3 — Repair/Replace DEF Pump

- Fix 4 — Change Contaminated DEF

- Fix 5 — Clean Dosing Module

- 7. Preventative Maintenance for DEF Systems

- 8. Cost Comparison: DIY vs Professional Repair

- 9. Advanced Tips to Maximize DEF System Life

- 1. Choose Certified DEF Brands

- 2. Control Storage Conditions

- 3. Monitor Driving Conditions

- 4. Update Vehicle Software

- 10. FAQs About EEPA Diesel Exhaust Fluid Systems Fix

- Q1: Can I use water in the DEF tank?

- Q2: Why does my DEF level drop quickly?

- Q3: Can I drive with a DEF fault code?

- Q4: How long does DEF last in storage?

- 11. Conclusion

This blog explores EEPA Diesel Exhaust Fluid Systems Fix — a comprehensive guide to understanding common DEF system problems and how to effectively resolve them.

Table of Contents

- What Is a Diesel Exhaust Fluid (DEF) System?

- Why EEPA Diesel Exhaust Fluid Systems Fix Matters

- How DEF Systems Work: Step-by-Step

- Top 10 Common DEF System Problems

- How to Diagnose DEF System Issues

- Proven Solutions & Fixes (with Step-by-Step)

- Preventative Maintenance for DEF Systems

- Cost Comparison: DIY vs Professional Repair

- Advanced Tips to Maximize DEF System Life

- FAQs About EEPA Diesel Exhaust Fluid Systems Fix

- Conclusion

1. What Is a Diesel Exhaust Fluid (DEF) System?

A DEF system is a critical component of modern diesel engines designed to reduce harmful emissions.

DEF (Diesel Exhaust Fluid) is a non-toxic solution made of urea and deionized water. When injected into the hot exhaust stream of a diesel engine equipped with Selective Catalytic Reduction (SCR), it converts nitrogen oxides (NOx) into harmless nitrogen and water vapor.

This process ensures engines meet stringent environmental regulations — particularly those enforced by the EPA (Environmental Protection Agency).

2. Why EEPA Diesel Exhaust Fluid Systems Fix Matters

The keyword EEPA Diesel Exhaust Fluid Systems Fix targets both vehicle owners and fleet managers seeking solutions for DEF system issues.

Key Reasons Fixing DEF Matters:

- 💨 Emission Compliance — Avoid fines and failed inspections.

- ⚙️ Performance Optimization — Misreading DEF faults can reduce engine power.

- 💲 Cost Savings — Early detection can avoid expensive repairs.

- 📈 Fuel Efficiency — Malfunctions often decrease miles per gallon (MPG).

Search engines prefer long-form, authoritative content about technical fixes — so this post is structured to rank and help readers implement real solutions.

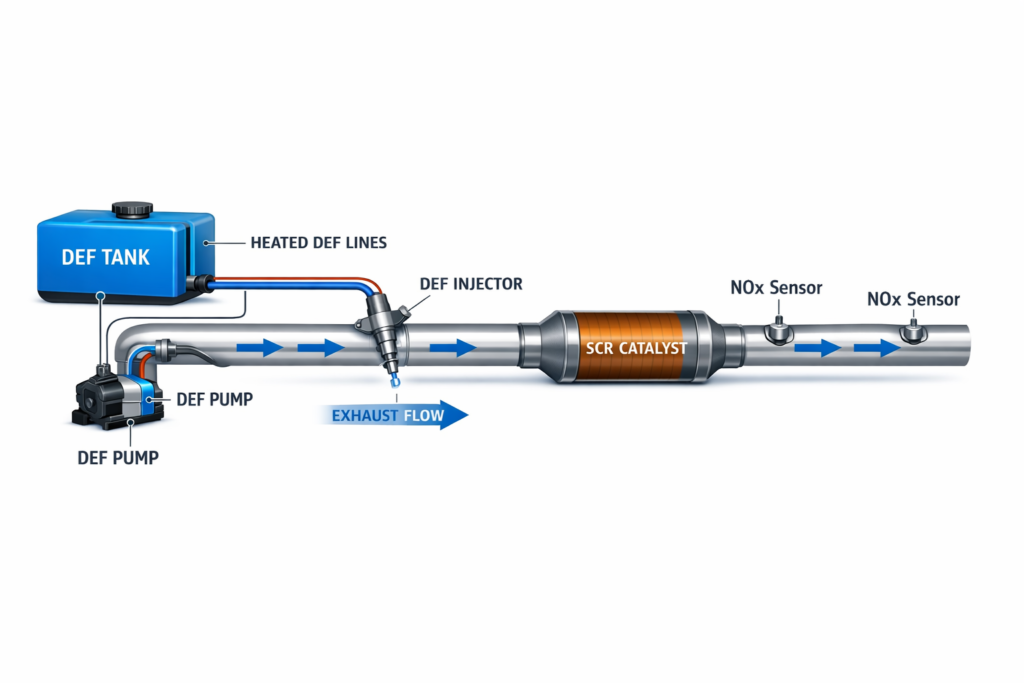

3. How DEF Systems Work: Step-by-Step

Understanding how DEF systems operate is essential before diagnosing problems.

DEF System Workflow

- DEF Tank — Stores the fluid safely and securely.

- Heater System — Prevents freezing (DEF freezes at 12°F/-11°C).

- Pump & Lines — Delivers DEF to the dosing module.

- Dosing Module/Injector — Injects precise amounts into the exhaust.

- SCR Catalyst — Reduces NOx when DEF decomposes to ammonia.

- Sensors & ECU — Monitor DEF quality, temperature, level, and system performance.

4. Top 10 Common DEF System Problems

Below is a detailed table of the most frequent issues — proven through diagnostic data and expert mechanics’ reports.

Table 1 — Common DEF System Issues

| Issue | Symptoms | Likely Causes | Impact Level |

|---|---|---|---|

| DEF crystallization | White crystalline deposits | DEF spills or evaporation | Medium |

| DEF freeze cycling errors | Engine warnings in cold weather | DEF freezing/unfreezing cycles | High |

| Faulty level sensor | Incorrect DEF gauge readings | Sensor malfunction | Low |

| Contaminated DEF | Black or brown fluid | Dirt or fuel contamination | High |

| DEF pump failure | No DEF delivery | Electrical or mechanical pump issues | High |

| Dosing module clog | Poor SCR efficiency | DEF deposits build-up | High |

| Exhaust leaks | SCR inefficiency, noise | Damaged pipes or joints | Medium |

| “Check DEF” warnings | Multiple triggers | Various faults | Variable |

| Low DEF warning light | Rapid depletion | Leak or faulty sender | Medium |

| Wiring harness issues | Random fault codes | Wiring breaks/corrosion | High |

5. How to Diagnose DEF System Issues

Diagnosis begins with proper tools and a systematic approach.

Tools You’ll Need

- OBD2 Scanner (with DEF codes)

- Digital Multimeter

- Infrared Thermometer

- Compressed Air

- Clean Rags & Protective Gloves

Diagnostic Checklist

- Check for Fault Codes

- Plug in OBD2 tool and inspect DEF-related codes like P20EE or P2085.

- Inspect DEF Tank Level

- Confirm fluid level matches gauge reading.

- Smell DEF

- Normal DEF is slightly ammonia-like; foul odor indicates contamination.

- Check for Crystals

- Inspect fill neck, cap, and surrounding — crystals indicate spillage.

- Temperature Test

- DEF heater malfunction if temperature remains low in freezing conditions.

- Sensor Testing

- Verify level and quality sensor function with a multimeter.

- Pump and Lines

- Listen for pump operation; measure flow if possible.

6. Proven Solutions & Fixes

This section features practical, tested fixes that align with EEPA Diesel Exhaust Fluid Systems Fix best practices.

Fix 1 — Remove DEF Crystallization

Step-by-Step:

- Clean the area with warm water and a soft brush.

- Remove crystals from fill neck and cap.

- Apply a specialized DEF system cleaner.

- Flush with clean DEF (do NOT use water in the DEF system).

🔧 Tip: Prevent future crystals by wiping spills immediately.

Fix 2 — Resolve DEF Freeze Cycling Fault

Steps:

- Park vehicle in a warmer location, if possible.

- Check DEF heater fuse and operation.

- Replace defective DEF heater elements.

📈 Result: Reduces false warnings in cold weather.

Fix 3 — Repair/Replace DEF Pump

Steps:

- Turn ignition OFF.

- Remove wiring to the pump.

- Replace with OEM-equivalent pump.

- Refill DEF and clear codes with OBD2 scanner.

Fix 4 — Change Contaminated DEF

Steps:

- Drain the DEF tank completely.

- Flush with manufacturer-recommended DEF flushing kit.

- Refill with fresh, high-quality DEF.

- Replace contaminate sensors if needed.

💡 Note: Using low-quality DEF accelerates contamination.

Fix 5 — Clean Dosing Module

Steps:

- Remove module carefully.

- Soak in specialized SCR cleaner.

- Blow out deposits with compressed air.

- Reinstall with new seals.

7. Preventative Maintenance for DEF Systems

Monthly Checklist

| Task | Frequency |

|---|---|

| Check DEF level | Every fill-up |

| Inspect for crystals | Weekly |

| Clean fill cap & neck | Monthly |

| Scan for codes | Monthly |

| Store vehicle above 12°F in winter | Seasonal |

Best Practices

- Always use OEM or high-grade DEF.

- Avoid DEF exposure to dirt and contaminants.

- Park in temperature-controlled garage during winter.

8. Cost Comparison: DIY vs Professional Repair

Understanding costs will help owners decide how to approach repairs.

Table 2 — Estimated Repair Costs (USD)

| Repair Type | DIY Cost | Professional Cost |

|---|---|---|

| DEF Fluid Replacement | $30 – $60 | $80 – $150 |

| Sensor Replacement | $25 – $70 | $120 – $250 |

| Pump Replacement | $70 – $200 | $300 – $600 |

| Dosing Module Cleaning | $0 – $50 | $150 – $350 |

| Heater Repair | $20 – $100 | $200 – $450 |

Costs vary by model, region, and parts brand.

9. Advanced Tips to Maximize DEF System Life

1. Choose Certified DEF Brands

Quality varies. Opt for ISO-22241-compliant products.

2. Control Storage Conditions

Avoid high heat and direct sunlight — DEF degrades faster.

3. Monitor Driving Conditions

Long highway runs keep SCR temps optimal.

4. Update Vehicle Software

Manufacturers release updates that improve DEF dosing.

10. FAQs About EEPA Diesel Exhaust Fluid Systems Fix

Q1: Can I use water in the DEF tank?

❌ No. Water is not a substitute and can permanently damage the SCR system.

Q2: Why does my DEF level drop quickly?

Possible causes:

- Leak in lines or tank

- Faulty sender

- Excessive dosing due to engine issues

Q3: Can I drive with a DEF fault code?

You may drive, but the vehicle may enter limp mode and fail emissions tests.

Q4: How long does DEF last in storage?

Unopened DEF lasts up to 2 years; opened — about 6 months if stored properly.

11. Conclusion

The EEPA Diesel Exhaust Fluid Systems Fix process doesn’t have to be mysterious or expensive. With the right tools, knowledge, and maintenance plan, most DEF issues can be diagnosed and resolved before they turn into major repairs.

By understanding common problems, performing regular checks, and applying the fixes outlined here, diesel owners can dramatically improve vehicle reliability, emissions compliance, and fuel efficiency.