# EPA Diesel Exhaust Fluid Systems Fix – Complete Guide, Causes & Fixes

If your diesel-powered vehicle starts throwing DEF warnings or your dash lights up with a DEF error, you’re facing the EPA diesel exhaust fluid systems fix head-on. This guide is written for car owners and DIY enthusiasts who want a clear, practical path to understanding, diagnosing, and addressing DEF system issues on North American and European diesel models. We’ll cover what DEF is, why problems happen, how to identify symptoms, a step-by-step troubleshooting approach, cost estimates, and smart preventive tips.

## What it is / explanation

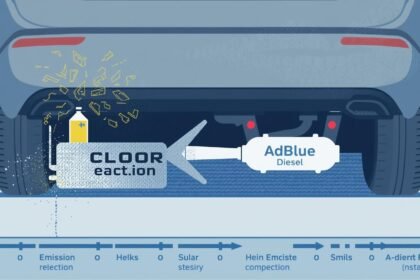

Diesel exhaust fluid (DEF) is a urea-water solution used in selective catalytic reduction (SCR) systems to reduce nitrogen oxide (NOx) emissions from diesel exhaust. In most modern diesels, DEF is stored in a separate tank, pumped into the exhaust stream, and sprayed into the SCR catalyst where it reacts with NOx to form harmless nitrogen and water. The EPA diesel exhaust fluid systems fix can involve the DEF tank, pump, heater, sensors, lines, and the SCR catalytic system, as well as the engine control unit (ECU) coordinating the process.

Key terms you’ll hear:

– DEF/AdBlue: the diesel exhaust fluid itself.

– SCR: Selective Catalytic Reduction, the system that reduces NOx.

– NOx sensors: monitor exhaust gases to control the SCR process.

– DEF pump and lines: deliver DEF from the tank to the SCR system.

– DEF heater: helps prevent DEF from freezing in cold climates.

– DEF quality/contamination: bad DEF can clog the system and trigger faults.

## Common causes

DEF problems don’t usually come from a single dramatic event. More often, they’re the result of a combination of issues or aging components. Common causes include:

– Low DEF level or empty DEF tank

– Contaminated or poor-quality DEF (non-OEM or old DEF)

– DEF pump failure or clogged DEF lines

– DEF injector or heater faults

– Faulty DEF quality sensor or NOx sensors

– SCR catalyst (or related hardware) damage or clogging

– Electrical faults or wiring harness corrosion

– DEF system leaks from cracked hoses, fittings, or cap seals

– Cold-weather effects (DEF freezing or reduced flow in subfreezing temps)

## Symptoms / how to identify the problem

Early detection can save you from expensive repairs. Look for these signs:

– Dashboard DEF warning lights or messages: “DEF system fault,” “Fill DEF,” “Urea system fault,” or similar.

– Reduced engine power or performance limits enforced by ECU to protect the system.

– Frequent regenerations or unusual exhaust smells (diesel exhaust with a chemical tang).

– Rough running or stalling after starting, especially in diesel trucks popular in North American markets.

– Visible DEF leaks around the tank, lines, or pump.

– Quick DEF consumption or inability to fill the tank fully.

– Nozzle or spray issues in the SCR injector; poor spray pattern or clogs.

– Error codes related to SCR, NOx sensor, DEF pump, or heater in a scan tool.

If you notice any of these, don’t ignore them. Some issues can escalate into more serious engine or exhaust system faults.

## Step-by-step troubleshooting guide

Follow these steps to diagnose many DEF system problems. Use safe practices, work in a well-ventilated area, and consult a professional if you’re unsure.

– Step 1: Read the codes

– Use an OBD-II scanner or a dealer-level tool to pull trouble codes (DTCs).

– Common codes point to DEF/NOx sensors, DEF heater, SCR catalyst efficiency, or pump faults.

– Note any codes and cross-check with the symptoms you observed.

– Step 2: Check DEF level and quality

– Confirm the DEF tank is not empty; refill with an OEM-grade DEF if needed.

– Inspect the DEF for contaminants (particles, color changes, or a gummy residue).

– If you suspect poor-quality DEF, flush and fill with fresh, reputable DEF.

– Step 3: Inspect DEF system hardware

– Look for visible leaks at the tank, pump, lines, and injector connections.

– Check DEF lines for kinks, cracks, or loose clamps.

– Inspect the DEF pump for unusual noise or failure indicators.

– Examine the DEF heater for proper operation (in cold climates).

– Step 4: Check sensors and electronics

– Inspect the NOx sensors and corresponding wiring for corrosion or broken connectors.

– Check the DEF quality sensor (if equipped) for mounting integrity and signal accuracy.

– Look for damaged or frayed wiring harnesses near the SCR components.

– Step 5: Check the SCR catalyst and exhaust flow

– If the SCR catalyst is clogged or damaged, you may see persistent NOx-related codes.

– Visual inspection isn’t always possible; a shop may perform a backpressure test or a catalyst evaluation with proper tools.

– Step 6: Verify software and calibration

– Some issues resolve with a software update or map reflash from a dealer.

– Ensure the ECU is correctly calibrated for the DEF system in your region.

– Step 7: Perform a controlled test drive (safely)

– After making a simple fix (like replacing a faulty sensor or refilling DEF), clear codes and drive to trigger a regeneration cycle to confirm the repair.

– If codes reappear or performance remains degraded, deeper diagnostics are required.

– Step 8: Isolate the problem

– If you have multiple symptoms or recurring codes, the fault may lie with a single component (pump, sensor, or SCR catalyst) or a wiring harness issue affecting several parts.

Tips for DIY-friendly diagnosis:

– Use OEM or vehicle-specific manuals for wiring diagrams and torque specs.

– Avoid mixing DEF with other fluids; never use windshield washer fluid or coolant in the DEF system.

– Don’t ignore DEF warnings; driving with an active DEF problem can trigger a hard set of limitations that reduce performance.

## When repair is possible vs when to visit a mechanic

– DIY-friendly fixes (often affordable and safe with basic tools):

– Replacing a faulty DEF level sensor or wiring harness if you’re comfortable with electrical work.

– Replacing a leaky DEF hose, clamps, or minor seals.

– Refilling DEF with fresh, quality fluid and cleaning the tank neck.

– Replacing a malfunctioning DEF pump, if you’re comfortable with accessing the pump location.

– Higher-risk or professional-needed fixes:

– SCR catalyst replacement or major SCR system overhaul.

– NOx sensor replacement that requires careful sensor handling and wiring diagnostics.

– ECU recalibration or software updates requiring dealer tools.

– Any suspected DEF contamination leading to internal engine or exhaust damage; this often requires professional inspection.

If you’re unsure or your vehicle is still under warranty, it’s wise to consult a qualified technician. Modern diesel systems are tightly integrated, and incorrect DIY work can create more problems or void warranties.

## Repair/Replacement Cost Estimates (USD)

Costs vary by vehicle make, model, and region, but here are typical ballpark figures to help you plan. These are ranges for parts and labor, not including taxes or shop fees.

– DEF pump replacement: $300 – $900 (parts + labor)

– DEF heater replacement (in-cold climates): $150 – $600

– DEF lines and fittings replacement: $100 – $400

– DEF level sensor replacement: $150 – $350

– NOx sensor replacement: $200 – $700

– SCR catalyst replacement (or SCR module): $2,000 – $8,000 or more

– Wiring harness repair related to DEF system: $100 – $500

– Software update / ECU reflash: $100 – $350 (dealer-level tools)

Important notes:

– Labor times can be lengthy for SCR-related repairs due to exhaust system access.

– OEM DEF fluid costs around $2–$4 per gallon; a typical tank holds 5–7 gallons, with variation by model.

– In some regions, diesel repair shops with specialized DEF equipment may offer flat-rate diagnostics or bundling of DEF-related services.

## Preventive tips

– Use only OEM or manufacturer-recommended DEF products and brands.

– Keep DEF in a cool, dry place and avoid exposing it to direct sunlight or extreme temperatures; do not freeze hot DEF as it expands and may damage lines (use a heater-enabled system if appropriate in winter climates).

– Check the DEF level regularly and top off as needed, particularly before long trips.

– Inspect the DEF cap, neck, and filler area for dirt or contamination when refilling.

– Avoid contamination: never fill DEF with engine oil, coolant, or other fluids; ensure your fueling area is clean.

– Schedule periodic SCR system checks during routine maintenance, especially if your vehicle has high mileage or operates in harsh or diesel-dense environments.

– If you notice consistent warning lights, address them promptly rather than driving with an inactive or partially functioning DEF system.

## FAQs

Q1: What exactly is DEF, and how does it work with the SCR system?

A1: DEF is a urea-water solution injected into the exhaust, where it decomposes into ammonia that reacts with NOx over the SCR catalyst, converting NOx into nitrogen and water. This reduces harmful emissions and helps the engine meet clean-air standards.

Q2: Can I drive my vehicle if the DEF system is failing?

A2: Some vehicles will allow limited driving with a DEF fault, but many will reduce power or enforce a forced engine shutdown to protect the exhaust system. Check your owner’s manual and avoid driving long distances until the fault is diagnosed.

Q3: Can I use any DEF brand I find at the pump?

A3: Not always. Use a reputable, OEM-approved DEF brand and ensure it’s within the shelf life. Mixed or contaminated DEF can clog the system and cause faults.

Q4: How long does a typical DEF system last?

A4: DEF systems are designed for long service life, but components like pumps, sensors, and wiring can wear out over time. Typical failure points occur after 100,000 miles (160,000 km) in some vehicles, but this varies widely by model and operating conditions.

Q5: Is a malfunctioning DEF system a warranty issue?

A5: Many DEF-related issues are covered under powertrain or emissions warranties, depending on mileage and the exact fault. Always check your warranty terms and service history with your dealer.

## Conclusion + CTA

Navigating the EPA diesel exhaust fluid systems fix can feel complex, but breaking it into clear steps—what DEF is, common culprits, how to identify symptoms, and a practical troubleshooting approach—empowers you to save time and money. Start with the basics: check DEF level and quality, read the codes, inspect hoses and the pump, and decide if a DIY fix is appropriate or if a professional is needed. Keeping your DEF system healthy not only avoids inconvenient warnings but also protects your engine, your wallet, and the environment.

Have car problems? Ask in the comments and I’ll help!