A vehicle’s transmission is one of the most critical and complex components in the drivetrain. Without it, your engine would be unable to efficiently deliver power to the wheels, making smooth acceleration, cruising, and hill climbing nearly impossible. Yet for many drivers, the transmission remains a mystery hidden beneath the car.

- What Is a Transmission?

- Why a Transmission Is Necessary

- Main Components of a Transmission

- 1. Clutch (Manual) or Torque Converter (Automatic)

- 2. Gears

- 3. Shafts

- 4. Synchronizers (Manual Transmissions)

- 5. Transmission Fluid

- How a Transmission Works: Step-by-Step Explanation

- Step 1: Engine Generates Power

- Step 2: Power Enters the Transmission

- Step 3: Gear Selection Determines Torque and Speed

- Step 4: Gear Engagement Transfers Power

- Step 5: Power Exits the Transmission

- Step 6: Vehicle Moves Efficiently

- How Manual Transmissions Work

- How Automatic Transmissions Work

- Other Types of Transmissions Explained

- Common Transmission Problems and Causes

- Importance of Transmission Maintenance

- Transmission and Fuel Efficiency

- Future of Transmission Technology

- Final Thoughts: How a Transmission Works

In this detailed guide, we’ll break down how a transmission works step by step, explain its main components, compare different types of transmissions, and explore why proper transmission function is essential for performance, fuel efficiency, and longevity.

What Is a Transmission?

A transmission is a mechanical system that transfers power from the engine to the wheels while adjusting torque and speed. Since an engine operates efficiently only within a specific RPM range, the transmission ensures that the wheels receive the correct amount of power at different driving speeds and conditions.

In simple terms:

- The engine creates power

- The transmission controls how that power is delivered

- The wheels convert it into motion

Why a Transmission Is Necessary

Engines cannot directly drive the wheels efficiently because:

- Engines spin very fast (thousands of RPM)

- Wheels rotate much slower

- Different driving situations require different torque levels

The transmission solves this by:

- Increasing torque at low speeds (for starting and climbing)

- Reducing engine RPM at high speeds (for fuel efficiency)

- Allowing reverse motion

- Enabling smooth acceleration and deceleration

Main Components of a Transmission

Before explaining how a transmission works step by step, it’s important to understand its core parts.

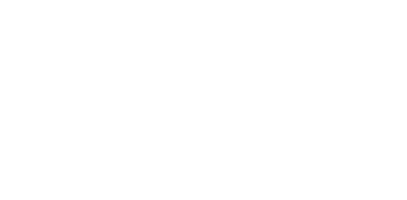

1. Clutch (Manual) or Torque Converter (Automatic)

- Connects and disconnects engine power

- Allows smooth gear changes

- Enables the car to stop without stalling

2. Gears

- Different gear ratios adjust torque and speed

- Lower gears = more torque, less speed

- Higher gears = less torque, more speed

3. Shafts

- Input shaft receives power from the engine

- Output shaft sends power to the driveshaft or differential

4. Synchronizers (Manual Transmissions)

- Match gear speeds during shifting

- Enable smooth, grind-free gear changes

5. Transmission Fluid

- Lubricates moving parts

- Cools the transmission

- Enables hydraulic pressure in automatics

How a Transmission Works: Step-by-Step Explanation

Let’s walk through exactly how a transmission works, from engine start to highway cruising.

Step 1: Engine Generates Power

The process begins when fuel ignites in the engine’s cylinders. This combustion turns the crankshaft, producing rotational power. However, this power is not yet usable for driving the wheels.

At idle:

- Engine RPM is low

- Vehicle remains stationary

- Transmission is disengaged or in neutral

Step 2: Power Enters the Transmission

Depending on the transmission type:

Manual Transmission

- The driver presses the clutch pedal

- The clutch disconnects the engine from the transmission

- Power flow temporarily stops

Automatic Transmission

- A torque converter uses fluid coupling

- Allows engine rotation even when the vehicle is stopped

- Gradually transfers power as throttle increases

Step 3: Gear Selection Determines Torque and Speed

Each gear has a specific gear ratio.

- First Gear

- High torque

- Low speed

- Used for starting and steep inclines

- Second & Third Gears

- Balanced torque and speed

- Used for city driving

- Higher Gears

- Lower torque

- Higher speed

- Ideal for highway cruising

The transmission selects the appropriate gear based on:

- Driver input (manual)

- Speed, throttle position, and load (automatic)

Step 4: Gear Engagement Transfers Power

Once a gear is selected:

- The chosen gear locks onto the shaft

- Power flows through the gear set

- Torque is multiplied or reduced as needed

In a manual transmission, the driver engages gears using:

- Clutch pedal

- Gear shifter

- Synchronizers

In an automatic transmission, this happens using:

- Planetary gear sets

- Hydraulic pressure

- Electronic control modules

Step 5: Power Exits the Transmission

After gear engagement:

- Power travels through the output shaft

- Moves to the driveshaft (RWD/AWD)

- Or directly to the differential (FWD)

The differential then:

- Splits power between wheels

- Allows wheels to rotate at different speeds while turning

Step 6: Vehicle Moves Efficiently

As speed increases:

- The transmission shifts to higher gears

- Engine RPM stays within optimal range

- Fuel efficiency improves

- Mechanical stress is reduced

This continuous adjustment is what makes modern driving smooth and efficient.

How Manual Transmissions Work

A manual transmission relies heavily on driver input.

Key Characteristics

- Driver selects gears manually

- Clutch pedal controls power flow

- Direct mechanical connection

Step-by-Step Manual Operation

- Driver presses clutch pedal

- Gear lever selects desired gear

- Synchronizers match gear speeds

- Clutch is released

- Power flows to wheels

Advantages

- Better driver control

- Lower maintenance costs

- Improved fuel economy in some cases

Disadvantages

- Requires skill

- Less convenient in traffic

How Automatic Transmissions Work

An automatic transmission shifts gears without driver intervention.

Key Components

- Torque converter

- Planetary gear sets

- Valve body

- Transmission control module (TCM)

Step-by-Step Automatic Operation

- Torque converter transfers engine power

- Sensors monitor speed and load

- Hydraulic pressure engages gear sets

- Computer selects optimal gear

- Smooth, automatic shifting occurs

Advantages

- Ease of use

- Smooth driving experience

- Ideal for city traffic

Disadvantages

- More complex

- Higher repair costs

Other Types of Transmissions Explained

Continuously Variable Transmission (CVT)

- No traditional gears

- Uses belts and pulleys

- Infinite gear ratios

Benefits

- Excellent fuel efficiency

- Smooth acceleration

Drawbacks

- Less engaging feel

- Can be costly to repair

Dual-Clutch Transmission (DCT)

- Two clutches for odd and even gears

- Lightning-fast shifts

Benefits

- High performance

- Efficient gear changes

Drawbacks

- Complex design

- Expensive maintenance

Common Transmission Problems and Causes

Understanding how a transmission works helps identify problems early.

Slipping Gears

- Worn clutch plates

- Low transmission fluid

Delayed Shifting

- Faulty sensors

- Dirty fluid

Grinding Noises

- Worn synchronizers

- Improper clutch use

Overheating

- Low fluid

- Towing beyond capacity

Importance of Transmission Maintenance

Regular maintenance extends transmission life significantly.

Essential Maintenance Tips

- Check fluid levels regularly

- Change transmission fluid on schedule

- Avoid aggressive driving

- Warm up vehicle in cold climates

A well-maintained transmission can last 200,000 km or more.

Transmission and Fuel Efficiency

A properly functioning transmission:

- Keeps engine in optimal RPM range

- Reduces fuel consumption

- Minimizes emissions

Modern transmissions with 6, 8, or even 10 gears allow:

- Better acceleration

- Lower highway RPM

- Improved overall efficiency

Future of Transmission Technology

Automotive transmissions continue to evolve.

Emerging Trends

- Electrified drivetrains

- Single-speed transmissions in EVs

- AI-controlled gear shifting

- Improved hybrid transmission systems

Electric vehicles often eliminate traditional transmissions entirely, relying on electric motor torque characteristics.

Final Thoughts: How a Transmission Works

Understanding how a transmission works step by step reveals just how essential this component is to vehicle performance and reliability. From multiplying torque during takeoff to maintaining fuel efficiency at highway speeds, the transmission acts as the bridge between raw engine power and controlled motion.

Whether manual, automatic, CVT, or dual-clutch, every transmission serves the same purpose: delivering power efficiently, smoothly, and reliably.

By maintaining your transmission and recognizing early warning signs, you can avoid costly repairs and ensure a long vehicle lifespan.